How Porcelain Slabs Are Made: A Journey from Artistry to Architecture

Porcelain slabs embody a harmonious blend of cutting-edge technology and timeless design. Known for their durability, elegance, and versatility, these surfaces have quickly become the go-to choice for luxury kitchens, bathrooms, fireplaces, and custom furniture. For architects, interior designers, and contractors seeking a refined yet low-maintenance alternative to natural stone, understanding how porcelain slabs are made is essential to specifying the right material for sophisticated environments.

At Zicana Boutique’s Porcelain Slabs Collection, we provide the world’s most exclusive and artistically engineered porcelain offerings. Below, we take a refined look at how these luxurious slabs come to life—step by step.

What Is Porcelain and Why Choose It?

Porcelain is a type of sintered ceramic material composed primarily of kaolin clay, feldspar, and silica. Through extreme heat and pressure, these raw materials are fused into an ultra-compact, non-porous surface resistant to heat, scratches, UV rays, and staining. The resulting slabs provide the visual richness of natural stone with enhanced performance benefits.

Homeowners with a passion for refined spaces, and design professionals working on bespoke residential or commercial spaces, choose porcelain for applications such as:

- Kitchen countertops and backsplashes

- Bathroom vanities and feature walls

- Indoor and outdoor flooring

- Furniture and fireplace surrounds

For extraordinary value, don't miss our Exclusive Offers Collection featuring porcelain slabs at special rates. And you can use promo code WELCOME100 for $100 off any order over $1,000.

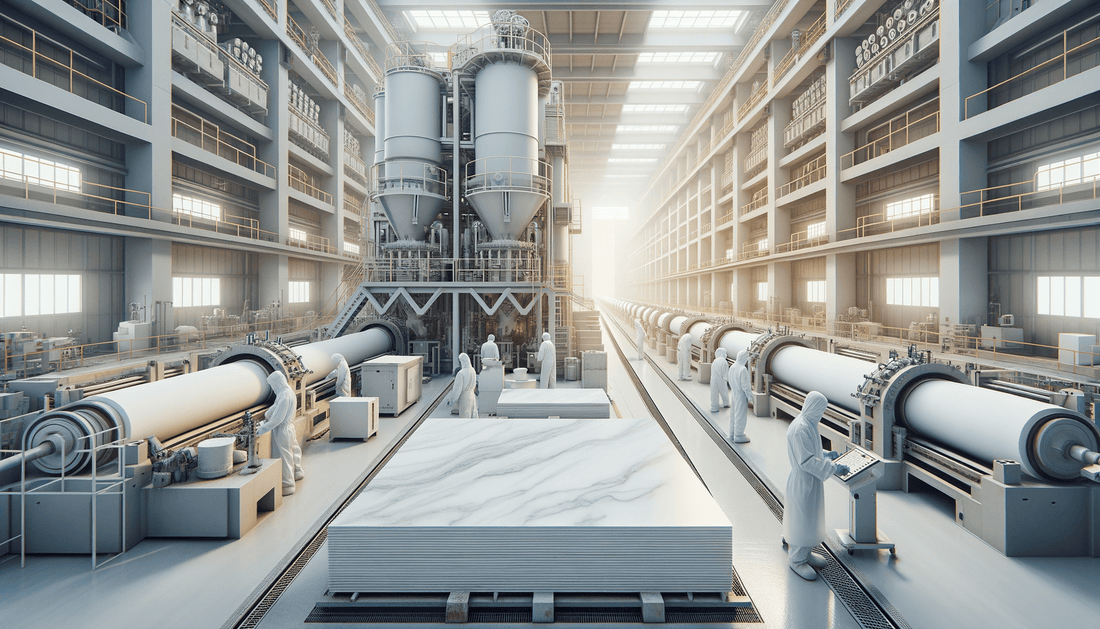

The Manufacturing Process: How Porcelain Slabs Are Made

The production of high-end porcelain slabs requires meticulous process design and advanced machinery. Each step ensures consistency, quality, and performance.

1. Raw Material Selection

The process begins with selecting the finest minerals—white kaolin clay, quartz, and feldspar. These ingredients undergo initial grinding and purification to achieve a fine homogenous mixture, known for its strength and purity.

2. Atomization to Powder

This refined mixture is converted into a fine, consistent powder through a spray-drying technique called atomization. This powder serves as the base for forming large-format slabs or tiles, depending on design requirements.

3. Pressing & Compaction

Using advanced continuous compaction technology, the atomized material is spread onto slab molds and compacted under extremely high pressure — up to 400 bars. This step ensures porcelain's signature density and uniform thickness for subsequent layers and finishes.

4. Digital Printing & Texture Application

Here, technical artistry shines. Large-scale digital printers apply ultra-realistic natural stone visuals across the compacted slab. This includes exquisite replicas of marble, quartzite, and even metallic or industrial aesthetics.

Textural elements—such as matte finishes, soft-touch, or high gloss—are also added at this stage through advanced surface treatments, giving each slab a unique tactile element.

5. Sintering in Kilns

The slabs are fired in kilns at temperatures exceeding 2,200°F (1,200°C) in a process known as sintering. This stage solidifies the slab, creating a surface that is heat-resistant, UV-stable, and impervious to liquids or oils.

6. Quality Control & Precision Cutting

Each slab undergoes rigorous quality controls, including visual inspection, thickness calibration, and performance testing. Precision cutting follows, where slabs are trimmed to bespoke sizes suitable for premium applications like made-to-measure custom countertops.

Porcelain’s Role in Luxury Design

When used in opulent residences or statement commercial spaces, porcelain’s performance characteristics make it ideal for both aesthetic impact and durability. Its resistance to etching, scratching, and bacteria makes it a standout for high-use areas—without sacrificing elegance.

Top designers pair porcelain with other luxury surfaces for layered effect. For instance, combine a veined porcelain backsplash with selections from our Onyx Slabs Collection or Furniture & Decor Collection for a soulful, balanced design statement.

FAQs: Common Questions About Porcelain Slabs

What is the difference between porcelain and sintered stone?

While both porcelain and sintered stone go through sintering, sintered stone incorporates additional elements like glass and natural stone particles, often yielding more robust or specialized formats. Explore more in our Sintered Stone Slabs Collection.

Are porcelain slabs suitable for outdoor spaces?

Yes. Porcelain’s UV resistance and non-porous nature make it ideal for exterior applications like terraces and outdoor kitchens, even in harsh climates.

How do porcelain slabs compare to natural stone in terms of maintenance?

Natural stones often require sealing and ongoing care to avoid etching and staining. Porcelain, by contrast, is low maintenance and rarely needs sealing—all while replicating the richness of stone found in our Granite Slabs Collection and beyond.

Can porcelain slabs be customized for furniture and walls?

Absolutely. Zicana Boutique offers Made-to-Measure Custom Countertops and surfaces that can be integrated into furniture, fireplaces, shower walls, and more with seamless sophistication.

Elevate Your Project with Luxury Porcelain from Zicana Boutique

Whether you’re a seasoned architect transforming a villa or a homeowner designing a dream space, understanding how porcelain slabs are made gives insight into their value and unrivaled beauty. From unparalleled resilience to iconic design aesthetics, porcelain continues to dominate the luxury design conversation.

Explore Zicana Boutique’s premium selection in the Porcelain Slabs Collection today, or take advantage of our Exclusive Offers Collection and apply code WELCOME100 for $100 off any order over $1,000. Our team of design consultants is always ready to help bring your vision to life with tailored guidance and curated recommendations.